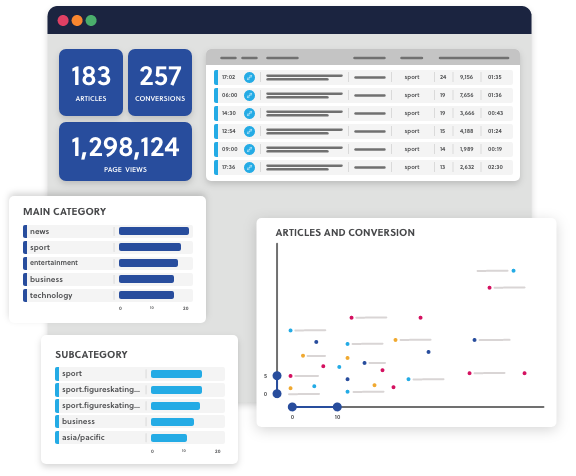

Better control of production in real-time and improved follow-up with detailed reporting can help reduce costs and save time. In printing and especially newspaper printing there are a number of areas that can be improved with a real-time tracking system that capture detailed information. Not only will there be savings on waste and production time, but also savings on time for generating valuable reports that gives insights to production improvements and problem areas.

There are five major areas of savings by implementing a tracking and reporting system, like MWM CopyTrack.

1. Overproduction and unaccounted copies (pad)

2. Time for generating reports

3. Waste reduction in general, from start, run and final waste numbers

4. General awareness of waste figures during production

5. Valuable reports to find costly problems and assist maintenance and job costing

1. Over Production

MWM CopyTrack is an excellent production tracking system and a helpful tool to almost eliminate overproduction (ie: printing more copies than needed).

With monitors showing production progress in real-time, at different locations in the production, it’s possible to have instant and accurate information about the total number of copies printed, how many are good copies and how many are waste copies from the folder to distribution.

With this information in hand it’s fast and easy to optimize production. To print only the correct number of copies needed and not just an average or “safe” number, is worth a lot of money. Let’s review the following example:

The Newspaper has taken an honest look at their operation and has determined the following is what happens for their average production:

The Newspaper has determined that they have an average cost of $0.20 per copy and they print 2 editions per day and run 365 days per year.

Annual savings on over production: $36,500 ($0.20 x 250 copies x 2 editions x 365 days)

A print site using MWM CopyTrack was able to reduce the over runs from 927 copies per print run down to 57-128 copies per print run on average.

2. Time for generating reports

MWM CopyTrack collect valuable production data and reports can be generated automatically, with accurate information when you need them. This can help to reduce the cost needed for having employees track the production data manually.

Manual routines for collecting and summarising daily reports (press and mailroom reports) can take 30-45 minutes per day, which adds up to 3,5-5,25 hours per week. This time could be better spent on raising the production efficiency and building motivation among the staff, which saves money.

Annual savings for this section: $5,460 to $8,190 (182 hours x $30.00 per hour / 273 hours x $30.00 per hour)

3. Start waste and general waste reduction

Better tracking with MWM CopyTrack makes it possible to reduce waste figures. This is accomplished through better production control and a more motivated staff, since they have a tool to see the current production status in all areas of the plant, which allows them to measure the waste in real figures, not just guesses.

Generally a newspaper printing organisation can eliminate most of their restarts or re-orders by being able to see real-time information during production and to track previous production average waste values. With this information they know how much they need to produce and can stop the presses when this amount is reached. Then, with accurate information, the mailroom/distribution will have enough papers and the presses will not need to be restarted.

Assume the following: Each copy costs $0.20 and three (3) restart can be eliminated per week. 250 copies are waste on each restart and papers are printed for 52 weeks a year.

Annual savings for this section: $7,800 ($0.20 x 3 restarts x 250 copies x 52 weeks)

4. General awareness of waste figures during production

In addition, general waste information displayed during the run have a positive effect on people when they know everyone can see the waste numbers produced at the moment. Experience have shown that this reduction is around 0.5%.

Assume the following: Newsprint consumption per year 10 000 ton Price per ton: $450

Annual savings for this section: $22,500

5. Valuable reports for improvement projects

With the tracking of production data such as good copies, waste copies and type of waste, stops and type of stops and time stamps from different events, CopyTrack will provide valuable reports needed for improvement projects.

Since CopyTrack will track all production stops, how much time they took, how many papers were wasted on restart and why they happened, action steps can be taken to eliminate them and improve.

Annual savings for this section can only be determined during system use, but there are usually several areas of improvement.

Ask yourself: “What would it be worth to know exactly what all of your downtime reasons are costing you?”

Want to discuss your possible savings or get a demo of MWM CopyTrack or other MWM Print 365 modules, contact us via this form