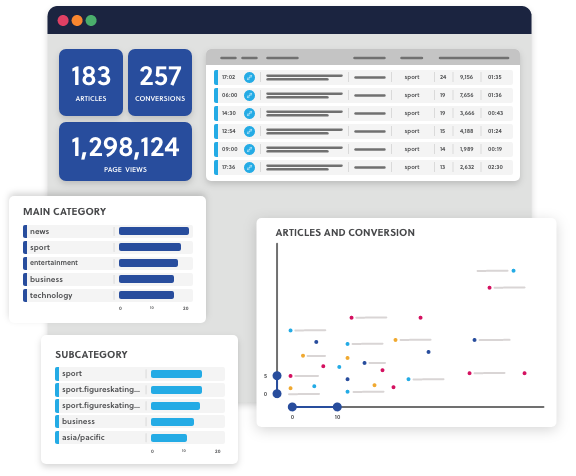

MWM ReelTrack can help any newspaper printing organisation obtain a better control of its most expensive raw material, which of course is newsprint. As the newsprint usage is often handled in different locations within an organisation, there is seldom a total view of the situation.

MWM ReelTrack offers a possibility to view the complete newsprint flow within the organisation. All newsprint activities can be tracked and handled and some of these tasks include:

- Paper supply and transport control

- Inventory control

- Damage claims control

- Run-ability/ print-ability/ web break reports

- Management information and reports

Optimize stock volume

To keep perfect inventory control of the volume of rolls for different newsprint types is one of the best ways to reduce stock volume and to know exactly what is available for today’s and future production.

Inventory control

MWM ReelTrack can give you an accurate inventory value as each individual roll has its own inventory value. This can provide precise newsprint cost for each production run.

Run-ability and web breaks

The performance of each roll is monitored. In this way we can rate each vendor/mill/lot operating performance. The system can also document the performance of each individual reel-stand, press operator and supervisor. Paster misses and web breaks can be tracked for each production run, operator and/or supervisor.

Tracks damages and roll defects

Keeping control of damages can be an efficient way of reducing web breaks, as well as, receiving transport damage claims. The damages are identified by codes so they can be separated into external and internal damages. Damage claims to the forwarder or paper mill can be reported from the system

Possible savings

One thing is certain, you will have a much better control of newsprint, the most costly material in the printing plant. Here are some interesting savings and benefits our customers see:

- Daily up-to-date information

- Reports to all management levels and departments using the same basic information

from the database. - Returned defect rolls have increased

- Damage claims due to run-ability problems with exact information have reduced continuing problems.

- Early detection of faulty batches of newsprint that causes production problems.

- Find your best suppliers and running conditions.

- Better run-ability as problems are eliminated because of knowledge gained.

- Newsprint cost for each production or product will give you facts to make better decisions.

Last but not least MWM ReelTrack offers more feedback to the mills and gives an improved co-operation that will be of benefit to all.

Workflow with ReelTrack

- Printing organisation places order for newsprint with mill

- Newsprint prices are added into ReelTrack

- Mill prepares shipment and send automatic manifest to the print organisation prior to shipment, which is imported into ReelTrack. Electronic manifests are used to reduce workload and keep better control of newsprint in transit

- ReelTrack´s ability to automatically receive manifest data and verifying the accuracy will provide the speed required by larger organisations or the demand for small operation to work with reduced manning

- Rolls arrive at plant

- Arrival and inventory checks are possible in order to control received and inventory compared to registered in ReelTrack.

- Rolls are scanned as they exit storage to enter preparation area to go onto reelstand

- Reelstand reports are prepared by ReelTrack during production for accurate consumption by product

- Partially consumed rolls are measured, entered into ReelTrack and put back at the preparation area or inventory

MWM ReelTrack, part of MWM Print 365