MWM CopyTrack: improved analysis, faster reaction

The Mittelbayerische Druckzentrum (MDZ) began operations in the south-eastern outskirts of Regensburg in 2010. Here, the team led by Managing Director Evelyn Köhler shows how the latest equipment can be used to produce newspapers and coldset commercial products highly efficiently and around the clock. The MDZ has now vastly improved its ability to analyze and react following its adoption of the MWM Group’s CopyTrack solution.

At its new plant, which is perfectly positioned for logistics purposes at the intersection of the A3 and B15 highways, the Mittelbayerische Druckzentrum installed a Manroland Colorman XXL (6 plates wide) web press. Although the press has four press towers and two folders, the fourth of these towers and one of the folders were intended as backups and over recent years up to three of the towers and one of the folder deliveries have been used for production. Consequently, the mailroom houses just one processing line, which uses Ferag kit, including an MSD inserting drum with ten Jetfeeders for inserts together with Multistack compensating stackers. A Segbert layer palletizer completes the array of equipment.

The plant, which also includes a logistics and sorting center, employs 150 people but the print center itself is a very lean operation, with a workforce of 25. 16 permanent staff work in postpress, which is managed by a legally separate company. On six days a week the MDZ produces a total of 110,000 copies of the 13 regional editions of the ”Mittelbayerischen Zeitung” as well as some 470,000 copies of the “Rundschau” advertising free sheet for its sister publishing company. It also prints 140,000 copies of a weekly for an external customer and 280,000 eight-pagers, which serve as carriers for collections of inserts.

Fully utilized

All in all, the Mittelbayerische Druckzentrum is so heavily utilized that it runs three shifts Monday to Friday and now both folders are used in parallel. In order to be able to operate at the optimum speed in both press hall and mailroom, all the production stages are decoupled and all the signatures buffered as rolls. Nevertheless, the pressure to stay on schedule is extreme. Semi commercial products are produced in a multitude of versions and distributed across Germany and so need to be finished precisely on time in order to be picked up by the carriers. There is no more than half an hour’s leeway each day.

It has become all the more important for MDZ to analyze the efficiency of current jobs, to optimize production and to react precisely and more rapidly to delays. Whilst, so far as the printing is concerned, the Pecom system makes a considerably amount of analytical data available, up until now the Regensburg company has lacked the ability to track production along its full length and to identify problems. The more a product is subdivided into versions, the more difficult it is to optimize allowances. In the past MDZ would build in substantial allowances as a precaution and even so have to reprint to make up shortfalls.

Shining a light into the postpress blackbox

In the past it was in the mailroom in particular where it was impossible to analyze how much wastage arose at which production stage and on which machines. This created an awkward situation, since postpress in Regensburg is handled by a separate company and the discussions would take place within the framework of a customer/supplier relationship.

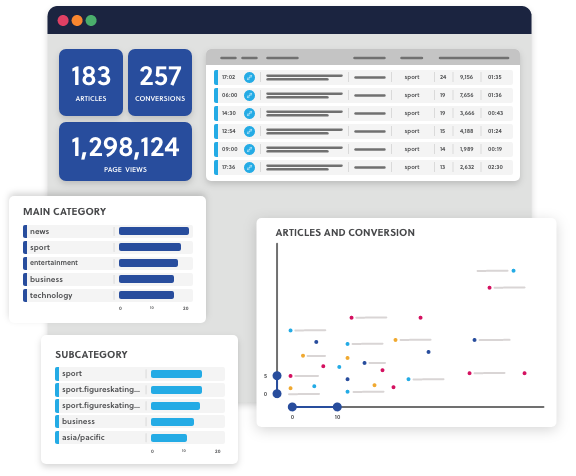

Partly as a result of conversations with satisfied users, MDZ decided to invest in the MWM Group CopyTrack system in 2018. CopyTrack is a software solution that allows data to be gathered regardless of the technology or manufacturer generating it. This can then be processed, displayed live in an individually customized way, and subsequently analyzed in detailed reports.

Evelyn Köhler, Managing Director of the Mittelbayerische Druckzentrum, comments:

“Postpress was previously a ‘blackbox’ for us; but with CopyTrack we are now able to probe it more deeply.”

MWM’s analysis identified 26 sensors already integrated into the production lines whose readings could be accessed and, for its part, the print center installed wiring to allow these readings to be forwarded to the MWM Data Collection Units.

Individual reading displays

One of MWM’s particular areas of expertise is its ability to evaluate and prepare data from a very wide range of machinery manufacturers and combinations of such manufacturers. At MDZ two Data Collection Units installed in the press hall and the mailroom receive the signals and process them in order to display the individual readings or aggregate readings, if, for example, several compensating stackers are being monitored together. The reading displays were jointly defined by the printer and the software supplier, and the various lines in the mailroom were planned so as to actively access the desired meters and their signals, assign them to the product and generate the corresponding display or report. The CopyTrack application sits on top of a normal database.

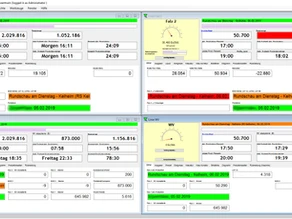

The numbers from CopyTrack are used in a wide variety of different ways. A large screen positioned above the plate delivery in the control desk area of the print center shows the current production status. This allows the printers to see what is happening in the mailroom, which is not visible from the control desk. Buffering of the signatures means that printing and postpress are not necessarily working on the same jobs. Conversely, the workers in the mailroom are able to see what is happening in the press hall. The four production lines or—more accurately—interfaces—whose status can be displayed on a split screen are the web press’s two folder deliveries, the inserting drum in the mailroom and the layer palletizer.

Traffic light display

It is also possible to replicate the display on the office screens of the Managing Director, the Technical Director, the team leaders and the job handlers. A standard traffic light scheme is used to allow the situation to be checked at a glance: green = production on schedule, amber = production behind schedule, red = line halted. Evelyn Köhler: “It’s a very simple and practical way of displaying the actual production status.” The screen display of the four production interfaces can also be minimized as a small window, allowing other programs to use the screen. In addition, after a line has been halted for 20 minutes the Technical Director receives an e-mailed warning.

Evelyn Köhler talks about her experience of production stoppages: “Usually the staff try to solve things themselves before they inform their superiors. However, this results in a certain loss of immediacy and we have very little slack if there are delays. After half an hour we need to take appropriate action such as pushing back carrier collection times or switching to backup production pathways.”

Usage-based servicing

CopyTrack has brought the Mittelbayerische Druckzentrum a range of benefits. First of all, it generates production documentation that can be presented to customers if, for example, problems in the inserting process can be traced back to the poor quality of the inserts that were supplied. CopyTrack also cuts down on the amount of shoe leather worn away in monitoring jobs. As Evelyn Köhler reports, “We need to visit the shop floor significantly less often in order to check on the current production status.” Over the medium term it allows service intervals on the individual machines to be switched from time intervals to usage-based servicing. CopyTrack can determine precisely how heavily used any production machine or any section of the gripper conveyor has been.

Overall, CopyTrack saves many of the production staff time as well as in the job scheduling department. Things like stoppages that previously had to be entered manually into Excel worksheets are now documented by the software automatically.

Evelyn Köhler and her team are already looking ahead. Once the benefits of CopyTrack have become the norm for all its staff, the Regensburg MWM user can see CopyTrack being extended upstream to a planning system.